AUSTRALIA WIDE LASER

CUTTING, FOLDING

& WELDING SERVICE

OUR MISSION

TO PROVIDE OUR CUSTOMERS WITH THE BEST SERVICE, QUALITY PARTS AND ON TIME DELIVERY. WE ACHIEVE THIS BY CONTINUALLY INVESTING IN OUR EMPLOYEES, TECHNOLOGY AND OPERATING SYSTEMS.

Since 1992, our national network continues to deliver on time, cost effective laser cutting to Australia’s leading large and small businesses.

OUR NATIONAL NETWORK DELIVERS ON TIME, COST EFFECTIVE LASER CUTTING TO AUSTRALIA’S LEADING LARGE AND SMALL BUSINESS.

NATIONAL REACH

Localised and national organisations trust our Australia-wide network. Our centralised MRP system enables your orders to be placed anywhere in Australia and manufactured in the LASER 3D branch of your choice.

EXPERIENCE COUNTS

LASER 3D understands that its employees play an integral part in our success.

The experience and knowledge of LASER 3D staff means continuous improvement in all facets of the laser cutting process – from order entry right through to delivery.

An investment in staff training coupled with advanced staff knowledge of the manufacturing industry enables better solutions and superior service to all customers.

PARTNERING

We’re more than a supplier. We work in partnership with our customers to streamline their production processes and assist in their product development.

The foundations of these partnerships results in successful long term business relationships.

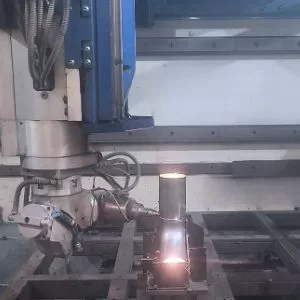

Supercar Muffler Baffle. 76mm diameter stainless steel tube with 5x8mm slots. Cut on the TruLaser Tube 7000.

TALK TO AN EXPERT TODAY

We pride ourselves on personal service. Contact us for an obligation free quote

OUR SERVICES

Laser 3D aims to deliver laser cut parts within 5 working days from approval subject to material availability.

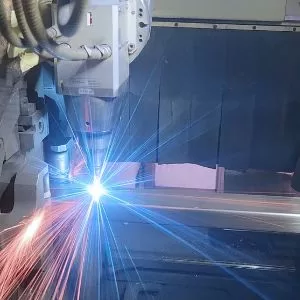

2 AXIS LASER CUTTING

With a beam that is focused to a pinpoint of 0.15mm for precise laser cutting...

5 AXIS LASER CUTTING

5-axis cutting provides the ability to move the laser cutting head through any position and direction...

LASER TUBE CUTTING

Two tube cutting laser systems allowing us to cut tube, RHS, Angle and C channel to your design...

CNC MACHINING

3 state of the art HAAS CNC Milling machines that provide increased precision and accuracy...

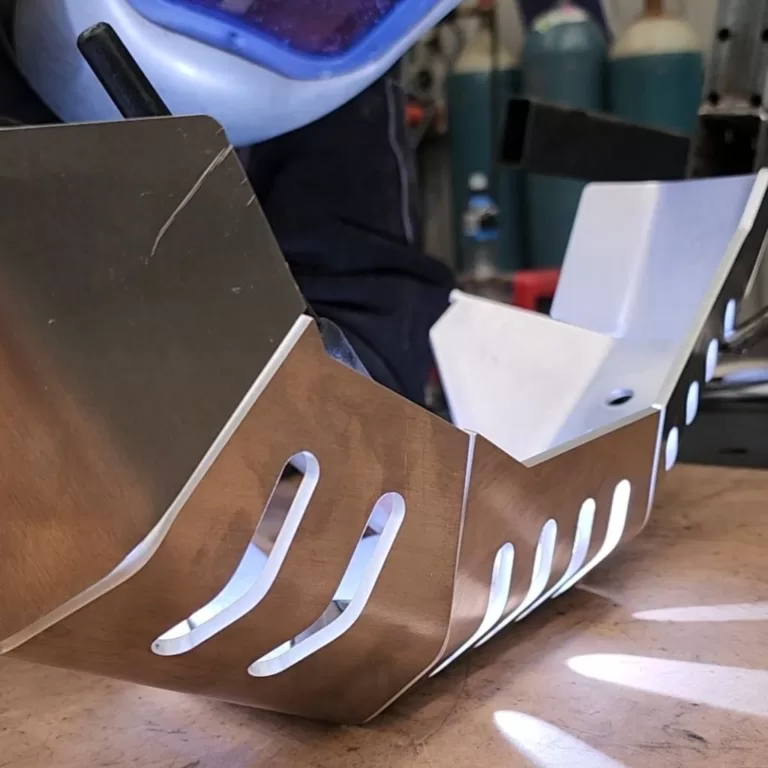

FOLDING

6 Press Brakes enabling us to fold complex and simple parts...

WELDING

Robotic and Manual MIG and TIG welding along with manual Spot-welding solutions...

CAD DATA / PART DRAWINGS

For fast service, all drawings/files should be emailed directly to your nearest LASER 3D branch.

Maximum files size we can receive via email is 20 MB.

We work with the following Software

TruTops Boost – Oseon

iTMS – Opto

Solidworks – draftsight – AutoCAD – PEPS

Edgecam – NextEngine Scan Studio HD

File formats for drawings

IGES – STEP

DXF – DWG

SLDPRT – SLDASM

when only the best will do

Many in the laser cutting industry consider TRUMPF to be the Rolls Royce of laser cutting machines.

The team at LASER 3D agrees.

That’s why we’re Australia’s largest owner of TRUMPF laser cutting machines.

Our national fleet features 15 TRUMPF lasers.

Our National Fleet

Our national fleet features 15 TRUMPF lasers

1x Trumpf L3030 – 3.2kW Co2 2 axis system for flat components Bed Size: 3000 x 1500

1x Trumpf L3050 – 5kW Co2 2 axis system for flat components Bed Size: 3000 x 1500

2x Trumpf L5030 – 5kW Co2 2 axis system for flat components Bed Size: 3000 x 1500

2x Trumpf L5030 10kW Fibre 2 axis system for flat components Bed Size:3000 x 1500

1x Trumpf 1005 – 5 3.2kW Co2 axis system for formed components. Bed Size: 3000 x 1500 x 750

1x Trumpf 7000 series 8 metre Tube/RHS cutting system 3.6kW Co2

2x Trumpf 5230 TruBend 230 Tonne 3 metre Press Brake

1x LVD 230 Ton 3 metre Press Brake

2x Haas VF-4 Machining Centre

1x Haas DM-2 Machining Centre

3x Trumpf L5030 6kW Co2 2 axis system for flat components. Bed Size:3000 x 1500

1x Trumpf L5030 6kW Co2 2 axis system for flat components Bed Size:3000 x 1500

1x Trumpf L5030 12kW Fibre 2 axis system for flat components Bed Size:3000 x 1500

1x Trumpf Trumabend C66 2 metre Press Brake

2x Trumpf 5230 TruBend 230 Tonne 3 metre Press Brake

1x Bystronic 150 Ton 3 metre Press Brake.

2x Trumpf L3030 – 4kW Co2 2 axis system for flat components Bed Size: 3000 x 1500

1x Mazak Fabri Gear 220 12 metre 2kW Co2 Tube/RHS

system

1x LVD 220 Ton 4 metre Press Brake

CONTACT LASER 3D

03 8710 4100

25-29 Arctic Court, Keysborough, VIC, 3713

LASER 3D commenced operation in Dandenong, Victoria in 1992. The longevity and success is in its ability to produce quality components, with exceptional service to a variety of industries throughout Victoria

The Victorian facility is the largest laser cutting operation within the LASER 3D network. LASER 3D’s modern machinery and experienced staff provide customers with cost effective manufacturing solutions.

LASER 3D is a national company and its strong market presence enables purchase of material at competitive prices with savings passed direct to customers.

NSW is serviced by VICTORIA and QUEENSLAND branches

VIC | 03 8710 4100

QLD | 07 3287 2880

The Victorian facility is the largest laser cutting operation within the LASER 3D network. LASER 3D’s modern machinery and experienced staff provide customers with cost effective manufacturing solutions.

Conveniently located close to Brisbane and the Gold Coast means existing and new Queensland LASER 3D customers can enjoy faster product turnaround and significant reductions in transport costs.

LASER 3D is a national company and its strong market presence enables purchase of material at competitive prices with savings passed direct to customers.

TASMANIA is serviced by our VICTORIAN branch

03 8710 4100

25-29 Arctic Court, Keysborough, VIC, 3713

The Victorian facility is the largest laser cutting operation within the LASER 3D network. LASER 3D’s modern machinery and experienced staff provide customers with cost effective manufacturing solutions.

LASER 3D is a national company and its strong market presence enables purchase of material at competitive prices with savings passed direct to customers.

07 3287 2880

25 Stephens Way, Luscombe QLD, 4212

Conveniently located close to Brisbane and the Gold Coast means existing and new Queensland LASER 3D customers can enjoy faster product turnaround and significant reductions in transport costs.

LASER 3D is a national company and its strong market presence enables purchase of material at competitive prices with savings passed direct to customers.

The NORTHERN TERRITORY is serviced by our QUEENSLAND branch.

07 3287 2880

25 Stephens Way, Luscombe, QLD, 4212

Conveniently located close to Brisbane and the Gold Coast means existing and new Queensland LASER 3D customers can enjoy faster product turnaround and significant reductions in transport costs.

LASER 3D is a national company and its strong market presence enables purchase of material at competitive prices with savings passed direct to customers.

08 8240 4888

4 Portsmouth Court, Gillman, SA, 5013

The Adelaide facility is the largest laser cutting operation in South Australia and is an ISO9001 quality certified job-shop.

A range of quality products is supplied to a variety of industries throughout South Australia including folding and fabrication, powder and other coating products.

LASER 3D is a national company and its strong market presence enables purchase of material at competitive prices with savings passed direct to customers.

WESTERN AUSTRALIAN is serviced by our SOUTH AUSTRALIAN Branch

08 8240 4888

4 Portsmouth Court, Gillman, SA, 5013

The Adelaide facility is the largest laser cutting operation in South Australia and is an ISO9001 quality certified job-shop.

A range of quality products is supplied to a variety of industries throughout South Australia including folding and fabrication, powder and other coating products.

LASER 3D is a national company and its strong market presence enables purchase of material at competitive prices with savings passed direct to customers.

Need Help?

FAQs

We're here to help.

Below you will find the answers to the most common questions.

If you don't find the answers you are looking for please call the customer service team in your state.

Do we cut brass, wood, MDF, acrylic etc

Our Co2 lasers aren’t suitable for cutting Copper or Brass, however in the first half of 2023 each facility is installing a new fibre laser which will be able to cut these metals.

We no longer cut timber or plastic due to environmental reasons.

Do we do any fabrication or extra processes ?

Yes, each facility have press brakes for folding and we have welding capabilities in Victoria and South Australia. We can also arrange for additional services such as plating or powder coating allowing us to supply you with a completed product.

We can also provide countersinking, taping, linishing and machining.

Do we cut tube?

Yes, we have tube cutting machines installed in Victoria and Queensland. Tube can be supplied and cut to your requirements in South Australia from our Melbourne factory.

Do we engrave ?

Our lasers do have the ability to engrave text or fold lines onto your laser cut components.

Our Melbourne factory is also capable of engraving logos onto a variety of metals.

Can we cut 25mm Mild Steel?

We can currently cut and supply up to 25mm mild steel. From May or capability will increase to 30mm

What thicknesses of Stainless Steel can we cut?

We can currently cut and supply from 0.55mm to 20mm and up to 25mm from May 2023

What thicknesses of Aluminium can we cut?

We can currently cut and supply from 0.8mm to 16mm and up to 20mm from May 2023

Can we cut Perforated sheet?

Yes we can

Can we supply mirror finish Stainless Steel?

Yes we can, up to 3mm thick

Can we cut holes in a formed part ?

Yes we can, up to 3mm thick

What file format do you require to produce a quote?

We prefer to quote from CAD files such as DXF or DWG. We can also accept 3D models and assemblies. If required we can also quote from PDFs

What files are needed to cut Rotary or Structural steel, i.e. RHS,SHS, PFC, Angle, Tube etc.?

We use Solidworks as our main 3D CAD software. The most common formats used to transfer files are STEP or IGES.

What is the maximum sheet size we can cut?

Our machines can accept up to 3050 x 1500 mm sheets.